Specializing in the production of water saving irrigation products

+86-13656349999

Categories

Contact Us

Address:Fengcheng Industrial Park, Laiwu District, Jinan City, Shandong Province, China

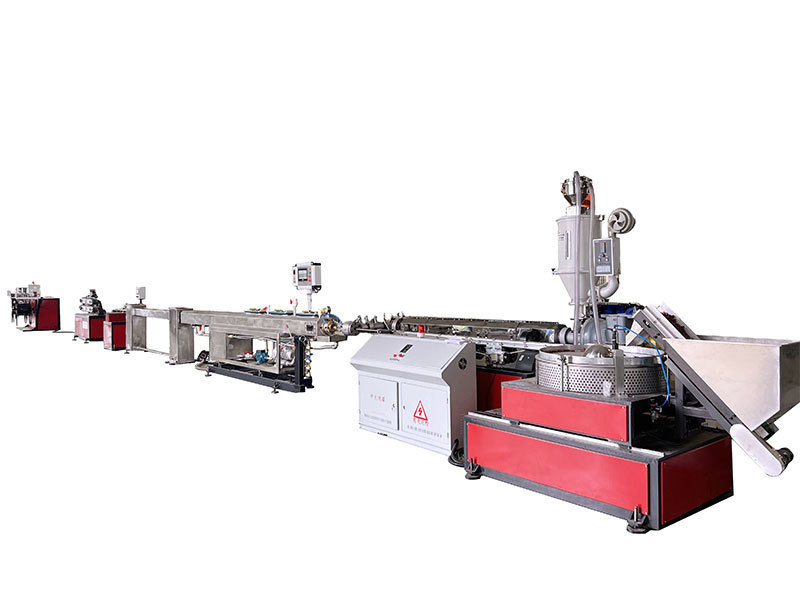

Inner Round Dripper Drip Irrigation Pipe Making Machine

Category:

Inner Round Dripper Drip Irrigation Pipe Making Machine

Enquiry hotline:

E-mail:

whatsapp:

Product details

Product:

|

Name: |

pipe diameter(mm) |

thickness(mm) |

Dripper space(cm) |

|

Drip pipe |

16,20mm |

0.6-1.2mm |

10-100cm |

Wroking condition:

|

humidity |

0-40℃ |

|

Power source |

3 phase 380v, 50Hz |

|

Installation power |

About 80kw |

|

Cooling water |

≤15℃ ≥0.3Mpa ~100L/min |

|

Compressor air |

5m3/h 0.4-0.6Mpa |

|

size |

30*3*2.6m(l*w*h) |

|

Line speed |

0-60m/min |

Production line compositon

|

Name |

|

Every part name |

No. |

|

Inner round emitter drip irrigation pipe production line

|

1 |

Dripper sorting and inserting systerm |

1 |

|

2 |

Automatic material feeding and drying system |

1 |

|

|

3 |

SJ-75×33/1 single screw extruder |

1 |

|

|

4 |

Die-head |

1 |

|

|

5 |

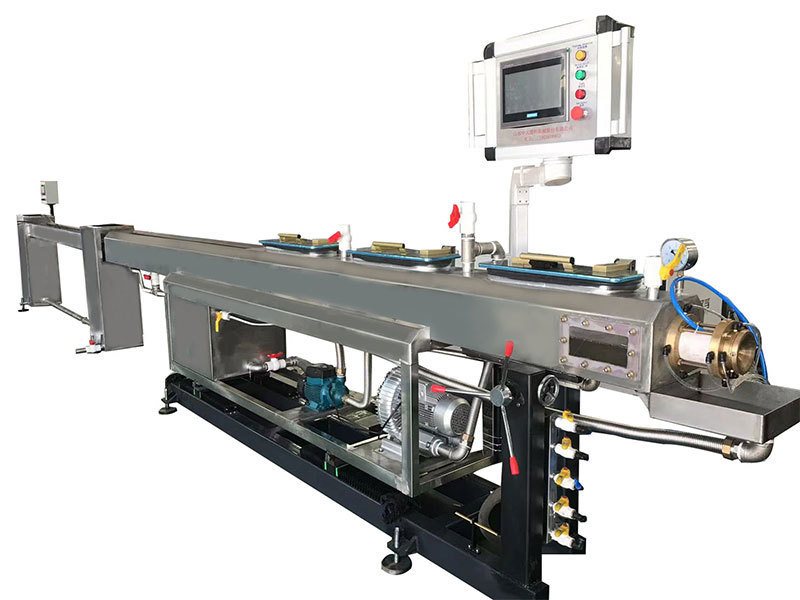

Vacuum sizing tank |

1 |

|

|

6 |

Cooling water tank |

1 |

|

|

7 |

Haul off part |

1 |

|

|

8 |

Punching machine |

1 |

|

|

9 |

Winding machine |

1 |

|

|

10 |

Electric cabinet |

1 |

Main technical parameter:

sorting and inserting system:

Infrared photoelectric sensor accurately controls the automatic feeding of the flat dripper

700mm sorting and inserting speed 300pcs/min

High efficiency extruder:

high output,low energy consumption and low noise

After quenching and tempering and nitriding heat treatment, the screw barrel screw has the characteristics of high temperature resistance, wear resistance, corrosion resistance and high strength, which greatly increases the service life; Reasonable and unique design of plasticizing section makes the surface of products smooth and glossy.

PLC control system:

high-performance PLC man-machine interface control system, and the operation process is convenient and easy to understand.

Vacuum sizing and cooling system:

Sizing system: a variety of alloys synthesize high-strength wear-resistant brass, which is easy to adjust.

Vacuum system: advanced pipeline layout design, good vacuum sealing and better cooling effect.

Haul off

Tractor: it adopts belt type pneumatic regulation traction

Punching system

Punching part: Servo punching, punching speed up to 300 times / min

winding machine:

Automatic winding,roller changing by manual

Meter setting: 300-500m / roll

Previous page

none

next page

Send Inquiry

Contact Us

Address:Fengcheng Industrial Park, Laiwu District, Jinan City, Shandong Province, China

Whatsapp:+8613656349999

More of our products

As a leading enterprise in the field of water saving in this region, the company has advanced equipment and strong technical force.

Official website